20 years of production experiences

Since 2001, after nearly 20 years of development, the company now has a group of experienced technical and management personnel, from heat load calculation selection to produce two-dimensional and three-dimensional design, through the introduction of domestic advanced welding equipment, Precision manufacture of high-frequency welded spiral fin tubes, quality management is equipped with special tooling equipment, complete testing methods, and process control. Products can be manufactured according to national standards, factory standards, or foreign standards, which can fully meet the needs of customers for mass production.

GLORYTUBETECH has Tremendous strength in scientific research

Over the years, with the strong support of various user units, the company has conducted cutting-edge technology docking with Harbin Institute of Technology, Tsinghua University, Shanghai Jiaotong University, and related research institutes to develop and produce high-quality finned tubes (high-frequency welded spiral finned tubes), Rolled aluminum fin tubes, energy-saving air heaters, and others. We have developed into one of the famous finned tube manufacturers in China.

Our products have been widely used in electric power, metallurgy, building materials, coal mines, chemicals, paper making, oil plants, leather, printing and dyeing, pharmaceuticals, vegetables, soy milk powder, malt extract, starch baking Dry, vacuum furnace manufacturing and building heating and other industries.

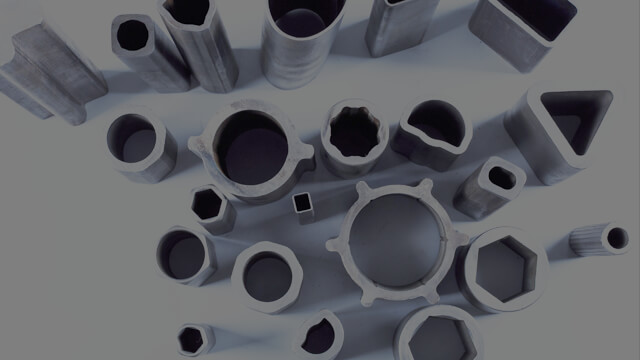

All types of finned tube manufacture

There are many types of finned tubes. At present, Glorytubetech mainly produces welded finned tubes, extruded fin tubes, roll-formed fin tubes, cast iron finned tubes.

Material includes carbon steel, stainless steel, aluminum, copper, etc.

we could supply composite metal fin tubes.

Laser welding finned tube

Compared with traditional high-frequency welding, laser welding can achieve a thinner base tube and higher fins, save materials, and improve production efficiency. The welding quality is good, the service life is extended, and the heat transfer resistance is reduced.

As one of the important finned tube manufacturers, We have introduced multiple laser welding production lines, which can fully guarantee the quality of the finned tubes and shorten the production cycle.